What Is Stronger: Iron or Steel?

In materials science and construction, understanding the relative strengths of different materials is essential. Iron and steel, though closely related, exhibit distinct characteristics that determine their suitability for various applications. Jump into the defining traits of these essential materials and discover what sets them apart.

Understanding Iron and Steel

Properties and Composition of Iron

Iron, symbolized as Fe on the periodic table, is a metallic element known for its high density and durability. It is primarily used as a raw material in construction, tools, and fabrication processes. Found abundantly in Earth’s crust, iron’s characteristics can vary depending on its purity and crystalline structure.

How Steel Is Made from Iron

Steel is derived from iron through an industrial process called alloying, which involves introducing carbon and other elements to molten iron. This modification significantly enhances the material’s strength, working properties, and resistance to wear and corrosion, making steel a staple material in manufacturing.

Steel’s Varied Compositions and Strengths

Steel comes in numerous grades and types, characterized by the added alloying elements such as chromium, nickel, or vanadium. Each formulation tailors the steel for specific uses, whether requiring increased tensile strength, flexibility, or corrosion resistance.

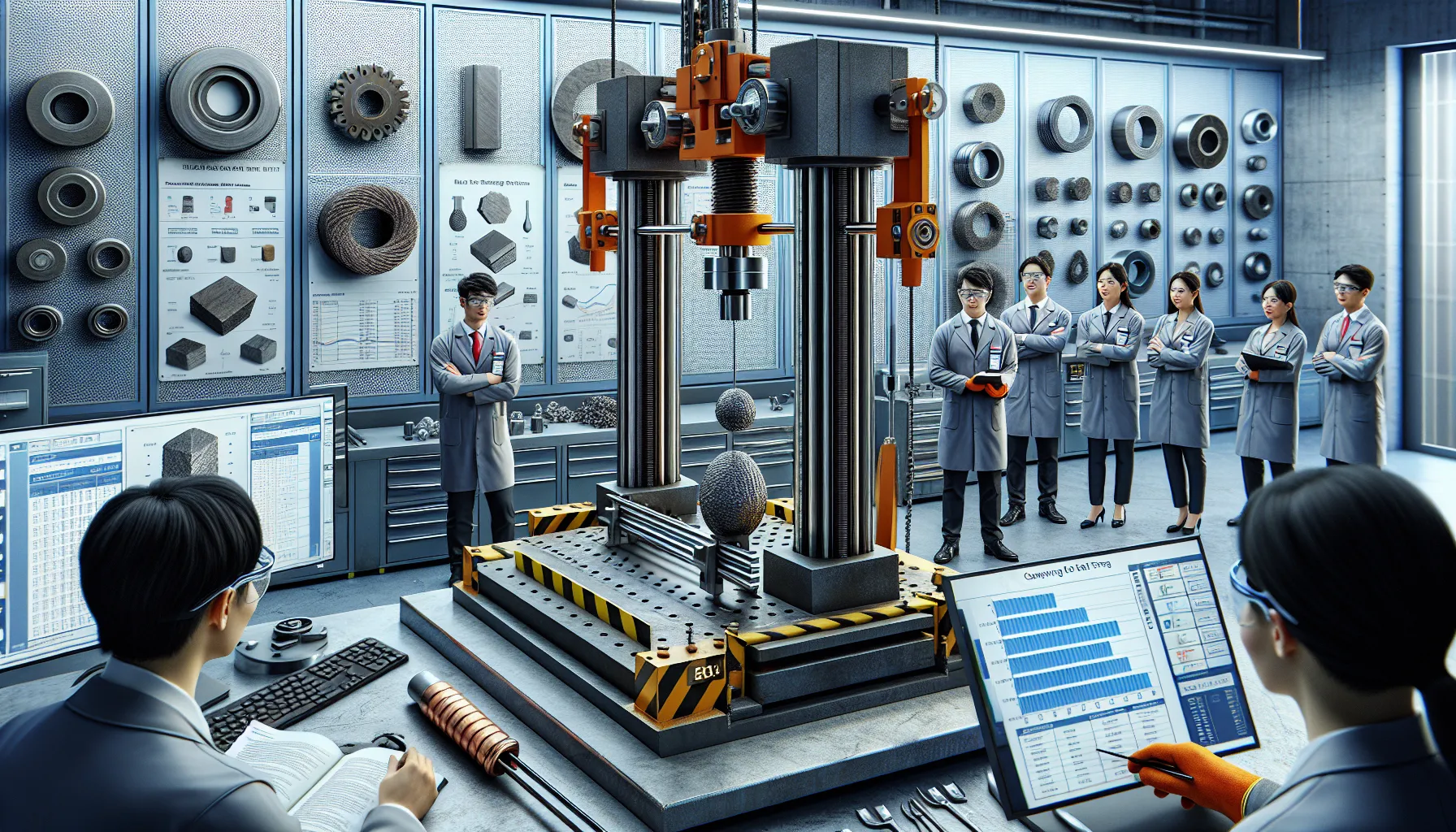

Factors That Determine Material Strength

Tensile and Compressive Strength

Material strength depends on its response to stresses, defined by tensile (resistance to pulling forces) and compressive (resistance to pressing forces) strength. Steel generally surpasses iron in these metrics due to its altered microstructure resulting from the alloying process.

The Role of Alloying Elements

Alloying elements significantly influence the physical properties of steel. Additions of carbon increase hardness, while elements like chromium and molybdenum improve resistance to damage and oxidation. Variations in the composition allow steel to be customized for precise performance needs across industries.

Comparison: Iron vs. Steel in Various Applications

Industrial and Construction Uses

Iron is commonly used in applications requiring high weight but lower flexibility, such as ornamental gates or counterweights. Steel’s superior strength and adaptability make it the material of choice for structures, machinery, and even modern tools.

Durability and Longevity Considerations

Steel often outperforms iron in environmental resistance, because of formulations like stainless steel that resist rust and corrosion. This longevity makes steel ideal for projects requiring extended service life under challenging conditions.

- Difference Between Turbocharger and Supercharger - January 17, 2026

- Difference Between Mirrorless and DSLR Cameras - January 17, 2026

- What Is Stronger: Iron or Steel? - January 17, 2026